Claw Type Grounding Wire of Central Cabinet

Grounding wire in power system: it is an important thing to protect operators when voltage is unexpectedly displayed on equipment and lines that have been cut off.

It is generally used for outdoor line and substation construction. Possible situations during maintenance:

1. Return current in the line

2. Electrostatic induction generated by nearby electrified bodies

3. Line electrification caused by incorrect switching on of the staff. At this time, the grounding wire connects the live line with the earth, and the travel is a closed loop to ensure the personal safety of the operator. Therefore, the grounding wire is also a safe return line.

- Descrição

- Detalhes rápidos

- Product Produce:

- Composição:

- O cabo de cobre macio é feito de cobre puro

- SPECIFICATIONS:

- Usage and precautions:

- Matters needing attention:

- Vantagens:

- FAQ:

- Embalagem e Entrega

- Contate-nos

Descrição

Claw Type Grounding Wire of Central Cabinet

Detalhes rápidos

Place of Origin: China (Mainland) Brand Name: XINCHENG

Product name: Claw type grounding wire of central cabinet, branch box grounding wire

Scope of use: indoor busbar, substation busbar Type: Claw type grounding wire

Model Number: A-type central cabinet (incoming switch)/ B type central cabinet (outgoing switch)

Constitute: Grounding wire, earth rod and earth clamp/earth needle

Application: used for short circuit grounding during outage maintenance of lines, power plants and substations

Characteristics: Temporary Grounding equipment

Rated Voltage: 0.1KV-550KV Kind: 3 phrases

Área da seção transversal do fio de Cooper:

10mm²/16mm²/25mm²/35mm²/50mm²/75mm²/90mm²/95mm²/120mm²/130mm²/150mm²; ou personalizados.

O escopo de temperatura para cobertura de proteção: ±55°C

Aterramento Flexível Fio de cobre Padrão: o comprimento e o diâmetro do fio podem ser personalizados de acordo com as necessidades do usuário.

The material of clamps: Aluminum/copper Strength: >=600N/mm2

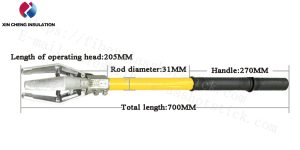

Standard of electric clamp: opening distance of electric clamp 35mm, large opening distance 130mm

A haste de operação do material é tubo de tecido de fibra de vidro super epóxi não alcalino

Rod length: 0.5m, 1m, 1.5m, 2m or customized.

Color: Red, green, yellow or or as per your requires Package: Portable bag, International Standard Package

Ground operating rod: IEC60855:1985. IEC61230:2008.

Product Produce:

Product Produce:

Grounding wire in power system: it is an important thing to protect operators when voltage is unexpectedly displayed on equipment and lines that have been cut off.

It is generally used for outdoor line and substation construction. Possible situations during maintenance:

- Retornar atual na linha

- Electrostatic induction generated by nearby electrified bodies

- Line electrification caused by incorrect switching on of the staff. At this time, the grounding wire connects the live line with the earth, and the travel is a closed loop to ensure the personal safety of the operator. Therefore, the grounding wire is also a safe return line.

Estrutura:

A linha de aterramento pelo terminal final do fio, curto, fio terra, nariz da fiação, rota de ônibus, o terminal final de aterramento (ou) aterramento temporário e barra de operação de aterramento, etc. braçadeira e dois tipos de grampo de fio de cobre puro, e seus fixadores correspondentes por tratamento de cromagem de metal. A operação da barra de aterramento USA força elétrica e mecânica são boas importações de resina epóxi avançada, fibra de vidro é delicada. Linha curta e tipo de linha de aterramento do multifio fino, o fio trançado de cobre recozido é revestido com uma camada de isolamento transparente macia e resistente a altas temperaturas. Os pontos de conexão da braçadeira de fio terra e da alavanca de isolamento têm dois tipos de fixação e tipo destacável, e para barramento de subestação e condutores aéreos, como uma variedade de estilos, o usuário pode escolher de acordo com a necessidade real.

The material operating rod is Super Epoxy Non-alkali Fiberglass Fabric Tube:

O fio de aterramento é a linha que conecta a terra diretamente. Também pode ser chamado de linha de loop de segurança. Quando ocorre o perigo, ele transfere a alta tensão diretamente para a terra, que é uma tábua de salvação. Fio de aterramento no sistema de energia: é uma ferramenta importante para garantir a equipe quando ocorre tensão inesperada nos equipamentos e linhas de interrupção. Para evitar choque de indução eletrostática ou fechamento incorreto de objetos carregados próximos, a haste de operação do material é tubo de tecido de fibra de vidro super epóxi não alcalino e a conexão de aterramento suave é feita de vários fios de fio de cobre de alta qualidade.

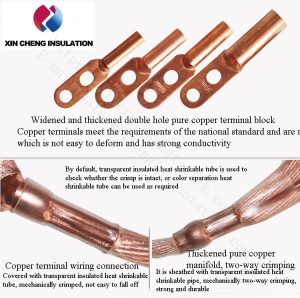

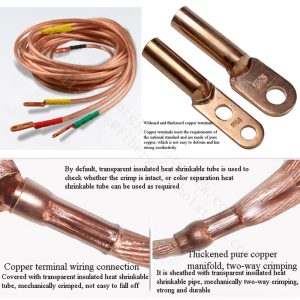

The grounding wire is made of multiple strands of high-quality soft copper wire twisted and covered with a soft, high temperature resistant transparent insulation (high cold resistant, soft and high temperature resistant PVC) protective layer, which can prevent the abrasion of the grounding wire in use and ensure the safety of operators in operation. This product is a security tool for electrical workers to prevent electric shock caused by induced voltage at the operation site.

Operating environment: – 25 ℃ to – 55 ℃. Relative humidity ≤ 90%

A new crimping process is adopted for the connection nose, bus duct, grounding copper wire and outer sheath. The soft connection can effectively prevent the copper wire strand from breaking when in use, and improve the reliability and service life of the grounding wire.

Composição:

Combinado pelo chumbo de fase, chumbo da terra, barra de terra e grampo de aterramento destacável.

Caracteres do produto: o gancho adota fundição por compressão de liga de alumínio leve, uso de pólo na fabricação de epóxi leve, alta resistência, excelente capacidade de condução elétrica. O fio de enfardamento usa fio de cobre de eletrólise.

The temperature scope for protective cover: +55°C

Especificação do produto: área transversal do fio de aterramento10mm²/16mm²/25mm²/35mm²/50mm²/75mm²/90mm²/95mm²/120mm²/130mm²/150mm²; ou personalizados.

A haste de aterramento com equipamento de braçadeira e fio de cobre foi feita de palitos de fibra de vidro, linha de fase, linha de chumbo de aterramento e grampo de aterramento (agulha de aterramento) .Lt foi amplamente utilizado no aterramento temporário de equipamentos industriais de energia industrial e de mineração.

1. A haste de aterramento portátil com braçadeira e equipamento de fio de cobre pode ser dividida em: fio de aterramento tipo barramento interno e fio de aterramento tipo circuito externo de acordo com o ambiente de uso.

2.According the voltage level, grounding rod with clamp and copper wire equipment divided into : 0.4kv ,6kv ,10kv ,33kv ,66kv,110kv ,220kv ,330kv ,500kv.

3. Varas de operação fio de cobre e braçadeira (agulha de aterramento) Haste de aterramento portátil com braçadeira e equipamento de fio de cobre Configuração de uso externo

O cabo de cobre macio é feito de cobre puro

O fio de cobre de alta tensão é feito de 99,95% de cobre roxo.

A resistência à terra é a seguinte: a resistência CC medida entre as pontas da fiação deve ser inferior a 0,79 m, 0,56 m, 0,40 m, 0,28 m, 0,21 m, 0,16 m, respectivamente, para várias seções de 25mm2, 35mm2, 50mm2 , 70mm2, 95mm2, 120mm2. Teste de tensão de suporte de frequência de energia da haste de operação, 10KV, 35KV, 63KV, 110KV, 220KV haste de aterramento respectivamente através de 45KV, 95KV, 175KV, 220KV, 440KV para suportar a tensão, mantenha um minuto sem avaria. As hastes de aterramento de 330KV e 500KV devem suportar tensão em 380KV e 580KV por cinco minutos sem interrupção.

Área da seção transversal do fio de Cooper:

10mm²/16mm² / 25 mm² / 35mm² /50 mm² /75mm²/90mm²/95mm²/120mm²/130mm²/150mm² or customized.

| Área da seção transversal/mm2 | 10 | 16 | 25 | 35 | 50 | 70 | 95 | 120 |

| Diâmetro do fio/mm | 4.2 | 5.7 | 7.5 | 8.78 | 11 | 12 | 16 | 17 |

| Diâmetro externo/mm | 7.3 | 7.8 | 9.6 | 11.2 | 12.6 | 16.5 | 21 | 22 |

| Valor de resistência Ω | 1.980 | 1.240 | 0.790 | 0.560 | 0.400 | 0.280 | 0.210 | 0.160 |

| Corrente de segurança A | 90 | 100 | 123 | 150 | 210 | 238 | 300 | 300 |

Aplicação de teste: o fio de cobre macio de 16 mm2 é adequado para fio de aterramento de segurança pessoal.

O fio de cobre macio de 25mm2 é adequado para tensão de 10KV-35KV.

O fio de cobre macio de 35mm2 é adequado para tensão de 110KV-220KV.

O fio de cobre macio de 50mm2 é adequado para tensão de 500KV.

O fio de cobre macio de 70 mm2 e 90 mm2 são adequados para aplicações de alta tensão com relativamente poucas aplicações.

SPECIFICATIONS:

SPECIFICATIONS:

| Modelo | Modelo | Voltage level | Cross sectional area | Specification of grounding wire | Configure | Scope of application |

|

XC-ZZ-JDX |

Conventional type |

0.4kv | 25mm² | 4*1.5+12M | 1 meter grounding rod | transformer substation |

| 10kv | 25mm² | 3*1+5M | 0.5 meter grounding rod | transformer substation | ||

| 35kv | 25mm² | 3*2+8M | 1 meter grounding rod | transformer substation | ||

| 110kv | 35mm² | 3*6+6M | Two 2 meter grounding rods | transformer substation | ||

| 220kv | 35mm² | 3*6+6M | Two 3 meter grounding rods | transformer substation | ||

| 500kv | 50mm² | 15M/PC*3PCS | Duckbill clamp | iron tower | ||

| 10kv | 25mm² | 3*1.5+10.5M | 1 meter grounding rod | line | ||

| 35kv | 25mm² | 3*2+18M | 1 meter grounding rod | line | ||

| 110kv | 35mm² | 15M/PC*3PCS | Duckbill clamp | line | ||

| 220kv | 35mm² | 15M/PC*3PCS | Duckbill clamp | line | ||

| Grounding wire of central cabinet | 10kv | 25mm² | 3*1+1.5M | 0.5m pole | Cable branch box | |

| Grounding wire of ring main unit | 10kv | 25mm² | 3*1+2M | Elbow cable head | Ring main unit |

Customer requirements can be customized according to customer requirements. The following parameters shall be provided for customized grounding wires:

- Applied voltage;

- Length of grounding rod and style of grounding terminal;

- Sectional area, length and connection mode of copper wire (split phase type or combined phase type);

- Ground terminal style (spiral clamp or ground nail).

Usage and precautions:

Usage and precautions:

Garanta a integridade do fio de aterramento e guarde -o em um local especial com boa ventilação e ambiente seco.

O uso deste fio de aterramento em equipamentos elétricos deve cumprir as disposições relevantes dos procedimentos de trabalho de segurança elétrica.

Antes de usar o fio de segurança, é necessário verificar a eletricidade e a descarga, confirme se o equipamento elétrico foi cortado e pendure o fio de aterramento antes da operação.

ANTES DE USAR DE FIO DE SEGURANCA, É NECESSÁRIO Veríntar a eletricidade e um desclarga, confirmando o equipamento elétrico para cortado e pêndão de fio de aterramento antes da operação.

Before using the security wire, routine inspection shall be carried out. It is prohibited to use the security wire when cracks, defects, poor contact of connecting parts, looseness, damage of insulation sheath and other defects are found.

Usage method:

- The correct use of the grounding wire of the central cabinet. Hang the grounding wire. After the line is verified to be free of voltage, the grounding wire shall be hung at both ends of the working section immediately. All branch lines that may be powered to the blackout line shall also be grounded. If the induced voltage is reflected on the outage line, the grounding wire shall be hung. At the same time, pay attention to prevent inductive electric shock when removing the grounding wire.

- When the multi-layer power lines erected on the same tower are hung with grounding wires, the low voltage shall be hung first, then the high voltage, and the lower layer shall be hung first, then the upper layer.

- When hanging the grounding wire, the grounding terminal shall be connected first, and then the conductor terminal. The grounding wire shall be connected reliably and shall not be twisted. The procedure for removing the grounding wire is the opposite. When installing and disassembling the grounding wire, the staff shall use insulating rods or wear insulating gloves, and the human body shall not touch the grounding wire. If the tower has no grounding downlead, temporary grounding rod can be used, and the depth of the grounding rod under the ground shall not be less than 0.6m.

- The grounding wire of the central cabinet shall be a complete set of grounding wires composed of grounding and short circuit conductors. The complete set of grounding wires shall be composed of multiple strands of soft copper wires, and its sectional area shall not be less than 25mm2. If the tower is used for grounding, each phase is allowed to be grounded individually, but the connection part between the tower and the grounding wire should be cleaned of paint and have a good contact.

Matters needing attention:

- Before the formal work, the whole set of grounding wires must be checked to see whether the flexible copper wire is broken, whether the sheath is damaged, whether a few screws are fastened, and whether the spiral of the hook is normal. If it does not meet the requirements, it shall be replaced or repaired in time before use.

- Before the grounding wire is hung, the line must ensure that there is no voltage and current before the grounding wire is hung. During the electrical inspection, the qualified electroscope with the same voltage level must be used. The purpose of electricity inspection is to confirm whether the power has been cut off at the site, which can eliminate the human error of power failure and non power failure, and prevent the electrified grounding wire.

- The grounding wire shall not be placed randomly and hung on the stay wire or metal tube in the running line. Its resistance is unstable, often too large, and does not meet the technical requirements. It may also make the metal tube live, causing harm to others.

- The grounding wire with corresponding specifications shall be selected according to different voltage levels, and the wire diameter of the grounding wire shall match the voltage level of the electrical equipment.

- It is not allowed to clamp the grounding wire onto the painted metal frame or metal plate, because the painted surface is an insulator, and the withstand voltage of the paint thickness reaches 10KV/MM, which can make the grounding circuit impassable and lose its protection.

- It is forbidden to use other metal wires instead of grounding wires. The contact of other metal wires is not firm, and the fault current will quickly melt the metal wires, disconnect the grounding circuit, and endanger the lives of workers.

- On site work, it is not allowed to hang the base county less or change the location of the grounding wire without authorization. The number of grounding wires and the location of the grounding wire are carefully considered by the work permit. If the grounding wire is hung less or the location is changed, the protection effect of the site will be reduced and the staff will be in a dangerous working state.

- Sign boards or temporary barriers shall be hung on the construction site.

- The grounding wire is double-edged and has a safety effect. Improper use will also cause damage. Therefore, the grounding wire should be removed in time after the work is completed. The switch with grounding wire will damage the electrical equipment and the stability of the power grid, which will lead to serious electrical accidents.

Before the electricity inspection, the grounding wire shall be prepared and its grounding terminal shall be connected to the terminal of the grounding grid (pole). When it is verified that the equipment or line has no voltage and is discharged, the maintenance equipment or line shall be grounded and three-phase short circuited immediately.

For all links that may be powered to the power failure equipment and lines, including all branches of the line or power failure equipment that may generate induced voltage, the grounding wire shall be installed at a visible position at the operation site. The distance between the grounding wire and the live part shall comply with the safety distance regulations.

When working on the indoor power transformation and distribution device, the grounding wire should be installed at the specified position of the bus or conductive part. These positions should not be painted with phase paint, and there should be special grounding signs. The outgoing terminal of the grounding grid shall be set at the appropriate position of the power transformation and distribution device, so that the grounding terminal of the grounding wire can be well connected here. The grounding resistance value of the terminal must be qualified

When installing the grounding wire, the grounding terminal must be connected first, and the live end of Houjie that has been cut off. When removing the grounding wire, the live end that has been cut off must be removed first, and then the grounding terminal can be connected. Grounding rods or insulating gloves shall be used for assembling and disassembling grounding wires.

The grounding wire operation must be carried out by two people. If the substation is on duty, only the grounding disconnector can be used for grounding.

Vantagens:

- Anti-humor. Bonito.

- Haste epóxi com leve peso e alta resistência

- Manutenção fácil; Operação fácil, estruturada de maneira flexível

- Bom desempenho de isolamento

- O grampo usa liga de alumínio ou fundição de compressão Cooper

- Stick Use a fabricação de fibra de vidro epóxi leve, excelente desempenho da condução elétrica

- Fio de aterramento feito de fio de cobre puro

- O escopo de temperatura para cobertura de proteção: ±55°C

FAQ:

P 1, você poderia aceitar o pedido de amostra e se for gratuito?

A Yes, we welcome the sample order to test and check quality. And the sample and the delivery fee are not free, as many samples are requested to be sent.

P 2, como você envia as mercadorias e quanto tempo leva para chegar?

A A amostra é geralmente transportada pela DHL, FedEx, UPS ou TNT Express. Escolheremos a maneira econômica expressa e transporte de acordo com a quantidade de mercadorias ou como os requisitos dos clientes. O tempo expresso é geralmente em torno de 3-7 dias úteis.

Q 3, você fornece o serviço personalizado e o OEM?

A Sim, está disponível.

Q 4, que tal o serviço pós -venda?

A qualquer dúvida, por favor, entre em contato conosco livremente! Vamos atendê -lo bem!

Nossa capacidade de oferta: 250.000 peças/peças por mês, mais específico você pode nos entender por e -mail.

Nossos serviços:

We are specialized in power and cable equipments and construction tools. According to customers’ need, we can provide the most suitable products and solutions. Ensuring the quality of products, we organize production and make delivery in time, solve the guests’ needs and problems perfectly.

Embalagem e Entrega

Detalhes da embalagem:

suitable packing for export. Economic Packing design which will save your transportation cost, or as customer requirements

1. Pacote de inside: Bolsa de nylon anti-sombra + caixa de caixa + cinto de tecido.

Embalagem de fora: caixa de caixa ou estojo de madeira e palete.

3.Deando a necessidade do cliente.

Porto: Xangai, Qingdao, Tianjin

Time de entrega: 7-15 dias

Contate-nos

Miss: Lydia

https://fiberglasshotstick.com

WeChat : 86-13752439076 WhatsApp: 86-13752439076

Mob: 86-13752439076 Fax: 86-22-60863016

http://www.frpinsulation.com