Special track grounding wire for electrified high-speed railway and subway

The role of conductor rail grounding wire is to prevent equipment and lines from suddenly coming on, eliminate the induced voltage, and discharge the residual charge as a temporary grounding device. The leakage current in the electrical equipment (the current that will threaten the personal safety of the operator) is discharged into the ground.

- Quick Details:

- Product description:

- Use method and precautions of DC27.5KV railway catenary grounding wire:

- Technical indicators:

- Precautions for use of grounding wire:

- FAQ

- Packaging & Delivery:

- Please Contact Us:

Quick Details:

Place of Origin: China (Mainland) Brand Name: XINCHENG

Product name: Special track grounding wire for electrified high-speed railway and subway

Scope of use: Electrified railway, high-speed railway, subway, etc.

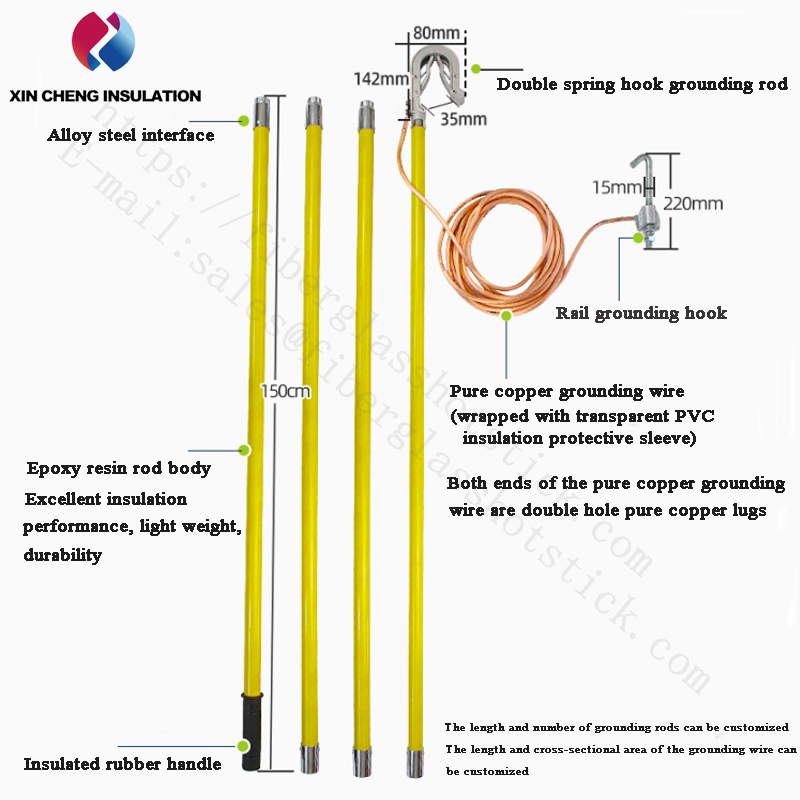

Constitute: Grounding wire, FRP grounding rod, grounding hook or grounding clamp

Application: used for the grounding of electrified railway conductor rail, catenary and underground railway

Rated Voltage: 1.5KV-500KV

Cooper wire’s cross section area: 25 mm² / 35mm² /50 mm² /75mm²/90mm²/95mm²/120mm²; or customized.

The temperature scope for protective cover: -25+55°C. Color: Red, green, yellow or or as per your requires

Grounding flexible copper wire standard: length and wire diameter can be customized according to user needs.

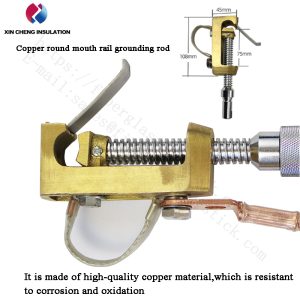

The material of clamps: Aluminum/copper Grounding hook material: galvanized high carbon steel

The material operating rod: Super Epoxy Non-alkali Fiberglass Fabric Tube

Rod length: 0.5m, 1m, 1.5m, 2m or customized. Package: Portable bag, International Standard Package

Product description:

The grounding wire is a favorable weapon for electrical workers to prevent high-voltage electric shock accidents caused by induced charges and sudden incoming calls, and is an ideal safety appliance for power transmission and transformation of power system, power distribution equipment and test equipment during power failure operation.

The role of conductor rail grounding wire is to prevent equipment and lines from suddenly coming on, eliminate the induced voltage, and discharge the residual charge as a temporary grounding device. The leakage current in the electrical equipment (the current that will threaten the personal safety of the operator) is discharged into the ground.

The contact rail grounding wire is a kind of portable short circuit grounding wire, which is used for subway and railway track. It is composed of insulated operating rod, wiring clamp, wiring terminal and grounding flexible copper wire.

Rail grounding wire Electrified catenary grounding rod:

- The length of insulated operating rod with yellow color is generally composed of multiple insulated rods, and the diameter of the rods is 36mm. Made of epoxy glass fiber, each section is screwed or connected and fixed with quick plug connection. Comply with GB13398-92 General Technical Conditions for Insulating Rods for Live Working.

- Length of grounding wire: 8m (flexible catenary). The length of grounding copper wire can be customized as required.

- The conductor end clamp shall be a grounding hook or grounding clamp.

- Sectional area of grounding wire: It varies according to the operating voltage, generally ranging from 25 mm2 to 120 mm2. The pure copper grounding wire adopts multi strand copper soft stranded wire and is covered with soft PVC insulating transparent insulating layer. The insulating layer material shall be flexible and free from cracking within the temperature range. Heat shrinkable sleeve is provided at the thread nose.

- The grounding wire shall meet the requirements of Portable Grounding and Grounding Short Circuit Devices for Live Working DL/T879-2004.

With the popularization of intelligent life, electric power is applied to all aspects of life, among which railway and subway are the two leading electric power applications. To keep the train running at a high speed, the railway and subway need high-voltage power as the driver, which continuously provides energy for the train to move forward. As high voltage electricity is involved, high voltage grounding wire will be used in the maintenance of railway catenary and metro rail. The common ones are DC1500V metro rail high voltage grounding wire and DC27.5KV catenary grounding wire.

Place of use: HVDC grounding wire is generally used for the grounding of electrified railway conductor rail, catenary and underground railway

Use method and precautions of DC27.5KV railway catenary grounding wire:

(1) After the power inspection, the construction equipment shall be grounded immediately after it is confirmed that the power has been cut off.

(2) Before operation, connect the grounding clamp of the grounding wire to the ground rail reliably, and then connect the conductor clamp connector to the end of the operating rod.

(3) Only then can the operator stretch the operating rod to the proper position.

(4) Move the operating rod slowly to hang it on the overhead conductor for construction, and observe that the operating rod shall be vertical to the overhead conductor. At this time, rotate the operating rod to reliably connect with the conductor and fasten it.

(5) The discharge place of the grounding wire shall be on both sides of the electrical circuit of the construction point to ensure that the construction personnel are within the reliable protection range.

(6) After the construction, the grounding wire shall be removed immediately, and the removal sequence shall be in strict accordance with the sequence of removing the overhead conductor end first and then the grounding end.

(7) Retract the grounding operating rod, and then remove the conductor clamp joints and store them in ventilated and dry places for reuse.

Technical indicators:

Technical indicators:

- Environmental conditions:

(1) Ambient temperature: – 25 ℃~+55 ℃

(2) Relative temperature: ≤ 90%

(3) Usage: indoor and outdoor rain free weather

- Product specification:

| Type | Voltage (KV) |

Total length of grounding rod (M) |

Cross sectional area of grounding wire (MM2) |

Length of grounding wire (M) |

Accessories and combination mode |

| 1 | 27.5KV | 4.5 | 25/50/70 | 8 | 1.5*3+Grounding hook or grounding clamp |

| 2 | 27.5KV | 6 | 25/50/70 | 8 | 1.5*3+Grounding hook or grounding clamp |

| 3 | 27.5KV | 4 | 25/50/70 | 8 | 2*2+Grounding hook or grounding clamp |

| 4 | 35KV | 3 | 35 | 8 | 1.5*2+Grounding hook or grounding clamp |

| 5 | 66KV | 3 | 35/50 | 8 | 1.5*2+Grounding hook or grounding clamp |

| 6 | 110KV | 3 | 50/70 | 8 | 1.5*3+Grounding hook or grounding clamp |

| 7 | 220KV | 3 | 70 | 8 | 1.5*2+Grounding hook or grounding clamp |

| 8 | 500KV | 4 | 90/120 | 8 | 2*2+Grounding hook or grounding clamp |

Note: The above product specifications are only conventional product specifications, which can be customized according to customer requirements, including the length of insulating operating rod, the cross-sectional area and length of grounding wire. In addition, the grounding hook or grounding clamp can also be configured according to customer requirements. We have many types of grounding clamp for customers to choose.

Precautions for use of grounding wire:

Precautions for use of grounding wire:

- The grounding wire shall be multi strand soft copper wire, and its section shall meet the requirements of short circuit current at the installation site, but shall not be less than 25mm2, and its length shall meet the needs of the work site; The grounding wire shall have a transparent outer sheath with a thickness of more than 1mm.

- The clamps at both ends of the grounding wire shall ensure that the grounding wire is in good contact with the conductor and the grounding device, easy to disassemble and assemble, has sufficient mechanical strength, and will not become loose when the large short circuit current is on or out. The connector (wire clamp or wire clip) of the grounding wire shall be in good contact after installation and have sufficient clamping force to prevent it from fusing due to poor contact or falling off due to the action of electric force when the amplitude of short circuit current is large.

- Before using the grounding wire, the appearance inspection shall be carried out. The screw of the grounding terminal clamp shall be firm and free of deformation, the conductor sheath shall be free of obvious damage and dirt, the conductor shall be free of broken strand, and the connection with the clamp shall be firm. The insulating rod body is free of cracks, damages and stains, and the test is qualified. The thread clamp screw is firm and the bayonet spring is qualified; The shackle shall be firm without deformation. If it is found that the strand is loose and the sheath is seriously damaged, the clamp is broken and loose, etc., it shall not be used. The inspection cycle is once a year.

- It is prohibited to use bare grounding wire without sheath.

- When installing the grounding wire, the human body shall not touch the grounding wire or ungrounded conductor to prevent inductive electric shock. The installation of grounding wire must be carried out by two people. Insulating rod and insulating gloves shall be used for the installation and removal of grounding wire.

- When installing grounding wire, the grounding terminal of grounding wire shall be installed first; After the electricity test proves that there is no electricity, the conductor end shall be connected immediately, and the sequence and sequence of removing the grounding wire shall be ensured to be in good contact. The opposite grounding wire shall not be connected by winding. Connect.

- During equipment maintenance, the number, position and number of ground wires hung on the analog panel shall be consistent with those listed in the work ticket and operation ticket, and with the ground wires installed on site.

- The personal security grounding wire is only used to prevent induction, and shall not be used as a substitute for grounding wire. Only after the working grounding wire is hung, can the personal security grounding wire be hung on the working phase.

- The personal security grounding wire shall be carried by the staff themselves. If the power is cut off on the 110kV and above same tower or adjacent parallel lines with inductive power, it shall be used on the working phase, and it is not allowed to use the method of virtual connection to ground the working junction. At the end, the staff shall remove the personal security grounding wire.

- The grounding wire must be fixed on the conductor with a special clamp. It is strictly prohibited to use the winding method for grounding or short circuit.

- Each group of grounding wires shall be numbered and stored in a fixed location, and the storage location shall also be numbered. The number of the grounding wire must be consistent with the number of the storage location, so as to avoid accidents caused by the wrong or forgotten removal of the grounding wire when the power outage maintenance is carried out in a more complex system.

- It is not allowed to connect the knife switch or fuse between the grounding wire and the working equipment, so as to prevent the equipment from losing grounding when they are disconnected, which may cause electric shock to the maintenance personnel.

Product preservation and precautions:

- The product shall be stored in a dry and corrosion free place with ambient temperature of – 25~55 ℃ and relative humidity of no more than 85% under packaging conditions.

- The grounding wire shall be stored and maintained by a designated person at a designated point, and shall be numbered and stored in a book. The storage location shall also be numbered, and the grounding wire number shall be consistent with the storage number.

- The disassembly and assembly of grounding wire shall be recorded and explained clearly during shift handover.

- The special grounding wire of conductor rail shall not be mixed with the grounding wire of other lines, and special line shall be paid attention to when receiving.

- Regular inspection records. The quality of the grounding wire shall be checked to see if there is corrosion and abrasion on the surface, if the PVC sleeve is damaged, or if the flexible copper wire is excessively oxidized or aged, so as not to affect the use effect of the grounding wire.

Product maintenance:

- The grounding wire shall not be twisted during use. When not in use, the soft copper wire shall be coiled and placed in the portable box. After the grounding wire is removed, it shall not be placed randomly or thrown anywhere. At the same time, attention shall be paid to the cleaning of the grounding wire. After use, the soft copper wire and the grounding rod shall be wiped clean to prevent sediment and debris from entering the pores of the grounding device, thus affecting the normal use.

- The special grounding wire for conductor rail shall be properly kept. Before each use, carefully check whether it is in good condition and whether the flexible conductor is exposed or broken. Otherwise, it shall not be used.

- The inspection cycle of portable short circuit grounding wire is once every four years, and the inspection items are the same as factory inspection.

- The special grounding wire for conductor rail that fails to pass the test shall be judged whether it can be used according to the short-circuit current and appearance inspection after being subjected to short circuit, and shall be scrapped generally.

FAQ

Q 1, Could you accept the sample order and if it is free ?

A Yes, we welcome the sample order to test and check quality. And the sample and the delivery fee are not free, as many samples are requested to be sent.

Q 2, How do you ship the goods and how long does it take to arrive?

A The sample is usually transported by DHL, Fedex, UPS or TNT express. We will choose the economical express and transport way according to the goods quantity, or as the requirements of client’s . The express time is usually around 3-7 working days.

Q 3, Do you provide the customized service and OEM?

A Yes, it is available.

Q 4, How about the after sale service?

A Any questions, please contact us freely! We will service you well !

More specific you can understand us through email.

Our Services:

We are specialized in power and cable equipment and construction tools. According to customers’ need, we can provide the most suitable products and solutions. Ensuring the quality of products, we organize production and make delivery in time, solve the guests’ needs and problems perfectly.

Packaging & Delivery:

Packaging Details:

suitable packing for export. Economic Packing design which will save your transportation cost, or as customer requirements

1.Inside packing: Anti-moisture nylon bag + Carton box + woven belt.

2.Outside packing: carton box or wooden case and pallet.

3.According customer requirement.

Port: Shanghai, Qingdao, Tianjin

Lead Time : 7-15days

Please Contact Us:

Miss: Lydia

https://fiberglasshotstick.com

E-mail:[email protected]

WeChat : 86-13752439076 WhatsApp: 86-13752439076

Mob: 86-13752439076 Fax: 86-22-60863016