Claw Type Grounding Wire of Central Cabinet

Grounding wire in power system: it is an important thing to protect operators when voltage is unexpectedly displayed on equipment and lines that have been cut off.

It is generally used for outdoor line and substation construction. Possible situations during maintenance:

1. Return current in the line

2. Electrostatic induction generated by nearby electrified bodies

3. Line electrification caused by incorrect switching on of the staff. At this time, the grounding wire connects the live line with the earth, and the travel is a closed loop to ensure the personal safety of the operator. Therefore, the grounding wire is also a safe return line.

- Descripción

- Quick Details:

- Product Produce:

- Composition:

- Soft cooper cable is made of pure copper :

- SPECIFICATIONS:

- Usage and precautions:

- Matters needing attention:

- Advantages:

- FAQ:

- Packaging & Delivery:

- Please Contact Us:

Descripción

Claw Type Grounding Wire of Central Cabinet

Quick Details:

Place of Origin: China (Mainland) Brand Name: XINCHENG

Product name: Claw type grounding wire of central cabinet, branch box grounding wire

Scope of use: indoor busbar, substation busbar Type: Claw type grounding wire

Model Number: A-type central cabinet (incoming switch)/ B type central cabinet (outgoing switch)

Constitute: Grounding wire, earth rod and earth clamp/earth needle

Application: used for short circuit grounding during outage maintenance of lines, power plants and substations

Characteristics: Temporary Grounding equipment

Rated Voltage: 0.1KV-550KV Kind: 3 phrases

Cooper wire’s cross section area:

10mm²/16mm² / 25 mm² / 35mm² /50 mm² /75mm²/90mm²/95mm²/120mm²/130mm²/150mm²; or customized.

The temperature scope for protective cover: -25+55°C.

Grounding flexible copper wire standard: length and wire diameter can be customized according to user needs.

The material of clamps: Aluminum/copper Strength: >=600N/mm2

Standard of electric clamp: opening distance of electric clamp 35mm, large opening distance 130mm

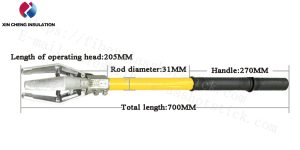

The material operating rod: Super Epoxy Non-alkali Fiberglass Fabric Tube

Rod length: 0.5m, 1m, 1.5m, 2m or customized.

Color: Red, green, yellow or or as per your requires Package: Portable bag, International Standard Package

Ground operating rod: IEC60855:1985. IEC61230:2008.

Product Produce:

Product Produce:

Grounding wire in power system: it is an important thing to protect operators when voltage is unexpectedly displayed on equipment and lines that have been cut off.

It is generally used for outdoor line and substation construction. Possible situations during maintenance:

- Return current in the line

- Electrostatic induction generated by nearby electrified bodies

- Line electrification caused by incorrect switching on of the staff. At this time, the grounding wire connects the live line with the earth, and the travel is a closed loop to ensure the personal safety of the operator. Therefore, the grounding wire is also a safe return line.

Structure:

The grounding line by wire end terminal, short, ground wire, wiring nose, bus route, the grounding end terminal (or) temporary grounding and grounding operation bar, etc. Line end and the grounding wire clip, high quality aluminum alloy die-casting clamp and two kinds of pure copper wire clip, and its matching fasteners by metal chrome plating treatment. Grounding bar operation USES electrical and mechanical strength are good imports of advanced epoxy resin, glass fiber is delicate. Short line and grounding line type of the multi-strand fine the annealed copper stranded wire is coated with a soft, high temperature resistant made of transparent insulation layer. Ground wire clamp and insulation lever connection points have fixity and detachable type two kinds, and for substation busbar and overhead conductors such as a variety of styles, user can choose according to actual need.

The material operating rod is Super Epoxy Non-alkali Fiberglass Fabric Tube:

Grounding wire is the line that connects the earth directly. It can also be called safety loop line. When danger occurs, it transfers high voltage directly to the earth, which is a lifeline. Grounding wire in power system: is an important tool to ensure staff when unexpected voltage occurs on the outage equipment and lines. In order to prevent electrostatic induction shock or mis-closing of nearby charged objects, The material operating rod is Super Epoxy Non-alkali Fiberglass Fabric Tube, and the soft ground connection is made of multiple strands of high-quality copper wire.

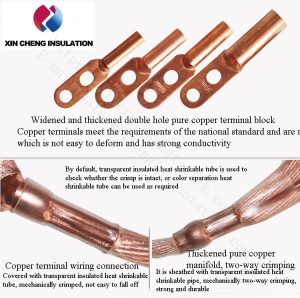

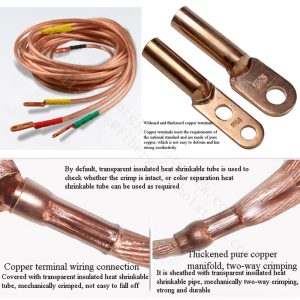

The grounding wire is made of multiple strands of high-quality soft copper wire twisted and covered with a soft, high temperature resistant transparent insulation (high cold resistant, soft and high temperature resistant PVC) protective layer, which can prevent the abrasion of the grounding wire in use and ensure the safety of operators in operation. This product is a security tool for electrical workers to prevent electric shock caused by induced voltage at the operation site.

Operating environment: – 25 ℃ to – 55 ℃. Relative humidity ≤ 90%

A new crimping process is adopted for the connection nose, bus duct, grounding copper wire and outer sheath. The soft connection can effectively prevent the copper wire strand from breaking when in use, and improve the reliability and service life of the grounding wire.

Composition:

Combined by phase lead, earth lead, earth bar and Detachable grounding clamp.

Product characters: Detachable grounding clamp adopts light aluminum alloy compression casting, pole use the light epoxy manufacture, hight strength, excellent ability of electric conduction. Baling wire uses electrolysis copper wire.

The temperature scope for protective cover: +55°C

Product specification: cross area of grounding wire10mm²/16mm² / 25 mm² / 35mm² /50 mm² /75mm²/90mm²/95mm²/120mm²/130mm²/150mm²; or customized.

Grounding rod with clamp and copper wire equipment was made from fiberglass sticks ,phase line ,grounding lead line and grounding clamp (grounding needle ) .lt was It is widely used in the temporary grounding of industrial and mining power industrial equipment.

1. Portable grounding rod with clamp and copper wire equipment can be divided into: indoor busbar type grounding wire and outdoor circuit type grounding wire according to the use environment.

2.According the voltage level, grounding rod with clamp and copper wire equipment divided into : 0.4kv ,6kv ,10kv ,33kv ,66kv,110kv ,220kv ,330kv ,500kv.

3. Operating sticks copper wire and clamp (grounding needle ) Portable grounding rod with clamp and copper wire equipment Outdoor use configuration

Soft cooper cable is made of pure copper :

High voltage grounding copper wire is made of 99.95% purple copper.

The resistance to the ground is as follows: the DC resistance measured between the wiring noses should be less than 0.79 m, 0.56 m, 0.40 m, 0.28 m, 0.21 m, 0.16 m, respectively, for various sections of 25mm2, 35mm2, 50mm2, 70mm2, 95mm2, 120mm2. Power frequency withstand voltage test of the operating rod, 10KV, 35KV, 63KV, 110KV, 220KV grounding rod respectively through 45KV, 95KV, 175KV, 220KV, 440KV to withstand voltage, keep one minute without breakdown. The 330KV and 500KV grounding rods should withstand voltage on 380KV and 580KV for five minutes without breakdown.

Cooper wire’s cross section area:

10mm²/16mm² / 25 mm² / 35mm² /50 mm² /75mm²/90mm²/95mm²/120mm²/130mm²/150mm² or customized.

| Cross section area/mm2 | 10 | 16 | 25 | 35 | 50 | 70 | 95 | 120 |

| Wire diameter/mm | 4.2 | 5.7 | 7.5 | 8.78 | 11 | 12 | 16 | 17 |

| Outside diameter/mm | 7.3 | 7.8 | 9.6 | 11.2 | 12.6 | 16.5 | 21 | 22 |

| Resistance value Ω | 1.980 | 1.240 | 0.790 | 0.560 | 0.400 | 0.280 | 0.210 | 0.160 |

| Safety current A | 90 | 100 | 123 | 150 | 210 | 238 | 300 | 300 |

Trial application: 16mm2 soft copper wire is suitable for personal security grounding wire.

25mm2 soft copper wire is suitable for 10KV-35KV voltage.

35mm2 soft copper wire is suitable for 110KV-220KV voltage.

50mm2 soft copper wire is suitable for 500KV voltage.

70mm2 soft copper wire and 90 mm2 are suitable for higher voltage applications with relatively few applications.

SPECIFICATIONS:

SPECIFICATIONS:

| Model | Escribe | Voltage level | Cross sectional area | Specification of grounding wire | Configure | Scope of application |

|

XC-ZZ-JDX |

Conventional type |

0.4kv | 25mm² | 4*1.5+12M | 1 meter grounding rod | transformer substation |

| 10kv | 25mm² | 3*1+5M | 0.5 meter grounding rod | transformer substation | ||

| 35kv | 25mm² | 3*2+8M | 1 meter grounding rod | transformer substation | ||

| 110kv | 35mm² | 3*6+6M | Two 2 meter grounding rods | transformer substation | ||

| 220kv | 35mm² | 3*6+6M | Two 3 meter grounding rods | transformer substation | ||

| 500kv | 50mm² | 15M/PC*3PCS | Duckbill clamp | iron tower | ||

| 10kv | 25mm² | 3*1.5+10.5M | 1 meter grounding rod | line | ||

| 35kv | 25mm² | 3*2+18M | 1 meter grounding rod | line | ||

| 110kv | 35mm² | 15M/PC*3PCS | Duckbill clamp | line | ||

| 220kv | 35mm² | 15M/PC*3PCS | Duckbill clamp | line | ||

| Grounding wire of central cabinet | 10kv | 25mm² | 3*1+1.5M | 0.5m pole | Cable branch box | |

| Grounding wire of ring main unit | 10kv | 25mm² | 3*1+2M | Elbow cable head | Ring main unit |

Customer requirements can be customized according to customer requirements. The following parameters shall be provided for customized grounding wires:

- Applied voltage;

- Length of grounding rod and style of grounding terminal;

- Sectional area, length and connection mode of copper wire (split phase type or combined phase type);

- Ground terminal style (spiral clamp or ground nail).

Usage and precautions:

Usage and precautions:

Ensure the integrity of the grounding wire, and store it in a special place with good ventilation and dry environment.

The use of this grounding wire on electrical equipment shall comply with the relevant provisions of electrical safety work procedures.

Before using the security wire, it is required to check the electricity and discharge, confirm that the electrical equipment has been cut off and hang the grounding wire before operation.

The personal security wire is a security tool to protect the construction personnel from electric shock due to contact with the corresponding voltage. It cannot replace the portable short circuit grounding wire specified in SD332-89.

Before using the security wire, routine inspection shall be carried out. It is prohibited to use the security wire when cracks, defects, poor contact of connecting parts, looseness, damage of insulation sheath and other defects are found.

Usage method:

- The correct use of the grounding wire of the central cabinet. Hang the grounding wire. After the line is verified to be free of voltage, the grounding wire shall be hung at both ends of the working section immediately. All branch lines that may be powered to the blackout line shall also be grounded. If the induced voltage is reflected on the outage line, the grounding wire shall be hung. At the same time, pay attention to prevent inductive electric shock when removing the grounding wire.

- When the multi-layer power lines erected on the same tower are hung with grounding wires, the low voltage shall be hung first, then the high voltage, and the lower layer shall be hung first, then the upper layer.

- When hanging the grounding wire, the grounding terminal shall be connected first, and then the conductor terminal. The grounding wire shall be connected reliably and shall not be twisted. The procedure for removing the grounding wire is the opposite. When installing and disassembling the grounding wire, the staff shall use insulating rods or wear insulating gloves, and the human body shall not touch the grounding wire. If the tower has no grounding downlead, temporary grounding rod can be used, and the depth of the grounding rod under the ground shall not be less than 0.6m.

- The grounding wire of the central cabinet shall be a complete set of grounding wires composed of grounding and short circuit conductors. The complete set of grounding wires shall be composed of multiple strands of soft copper wires, and its sectional area shall not be less than 25mm2. If the tower is used for grounding, each phase is allowed to be grounded individually, but the connection part between the tower and the grounding wire should be cleaned of paint and have a good contact.

Matters needing attention:

- Before the formal work, the whole set of grounding wires must be checked to see whether the flexible copper wire is broken, whether the sheath is damaged, whether a few screws are fastened, and whether the spiral of the hook is normal. If it does not meet the requirements, it shall be replaced or repaired in time before use.

- Before the grounding wire is hung, the line must ensure that there is no voltage and current before the grounding wire is hung. During the electrical inspection, the qualified electroscope with the same voltage level must be used. The purpose of electricity inspection is to confirm whether the power has been cut off at the site, which can eliminate the human error of power failure and non power failure, and prevent the electrified grounding wire.

- The grounding wire shall not be placed randomly and hung on the stay wire or metal tube in the running line. Its resistance is unstable, often too large, and does not meet the technical requirements. It may also make the metal tube live, causing harm to others.

- The grounding wire with corresponding specifications shall be selected according to different voltage levels, and the wire diameter of the grounding wire shall match the voltage level of the electrical equipment.

- It is not allowed to clamp the grounding wire onto the painted metal frame or metal plate, because the painted surface is an insulator, and the withstand voltage of the paint thickness reaches 10KV/MM, which can make the grounding circuit impassable and lose its protection.

- It is forbidden to use other metal wires instead of grounding wires. The contact of other metal wires is not firm, and the fault current will quickly melt the metal wires, disconnect the grounding circuit, and endanger the lives of workers.

- On site work, it is not allowed to hang the base county less or change the location of the grounding wire without authorization. The number of grounding wires and the location of the grounding wire are carefully considered by the work permit. If the grounding wire is hung less or the location is changed, the protection effect of the site will be reduced and the staff will be in a dangerous working state.

- Sign boards or temporary barriers shall be hung on the construction site.

- The grounding wire is double-edged and has a safety effect. Improper use will also cause damage. Therefore, the grounding wire should be removed in time after the work is completed. The switch with grounding wire will damage the electrical equipment and the stability of the power grid, which will lead to serious electrical accidents.

Before the electricity inspection, the grounding wire shall be prepared and its grounding terminal shall be connected to the terminal of the grounding grid (pole). When it is verified that the equipment or line has no voltage and is discharged, the maintenance equipment or line shall be grounded and three-phase short circuited immediately.

For all links that may be powered to the power failure equipment and lines, including all branches of the line or power failure equipment that may generate induced voltage, the grounding wire shall be installed at a visible position at the operation site. The distance between the grounding wire and the live part shall comply with the safety distance regulations.

When working on the indoor power transformation and distribution device, the grounding wire should be installed at the specified position of the bus or conductive part. These positions should not be painted with phase paint, and there should be special grounding signs. The outgoing terminal of the grounding grid shall be set at the appropriate position of the power transformation and distribution device, so that the grounding terminal of the grounding wire can be well connected here. The grounding resistance value of the terminal must be qualified

When installing the grounding wire, the grounding terminal must be connected first, and the live end of Houjie that has been cut off. When removing the grounding wire, the live end that has been cut off must be removed first, and then the grounding terminal can be connected. Grounding rods or insulating gloves shall be used for assembling and disassembling grounding wires.

The grounding wire operation must be carried out by two people. If the substation is on duty, only the grounding disconnector can be used for grounding.

Advantages:

- Anti-moisture. Nice looking.

- Epoxy rod with light weight and high strength

- Easy Maintenance; easy operation, flexibly structured

- Good insulation performance

- The clamp use aluminum alloy or Cooper compression casting

- Stick use the light epoxy fiberglass manufacture, excellent performance of electric conduction

- Grounding wire made of pure copper wire

- The temperature scope for protective cover :+55°C

FAQ:

Q 1, Could you accept the sample order and if it is free ?

A Yes, we welcome the sample order to test and check quality. And the sample and the delivery fee are not free, as many samples are requested to be sent.

Q 2, How do you ship the goods and how long does it take to arrive?

A The sample is usually transported by DHL, Fedex, UPS or TNT express. We will choose the economical express and transport way according to the goods quantity, or as the requirements of client’s . The express time is usually around 3-7 working days.

Q 3, Do you provide the customized service and OEM?

A Yes, it is available.

Q 4, How about the after sale service?

A Any questions, pls contact us freely! We will service you well !

Our supply ability: 250,000 Piece/Pieces per Month, More specific u can understand us through email.

Our Services:

We are specialized in power and cable equipments and construction tools. According to customers’ need, we can provide the most suitable products and solutions. Ensuring the quality of products, we organize production and make delivery in time, solve the guests’ needs and problems perfectly.

Packaging & Delivery:

Packaging Details:

suitable packing for export. Economic Packing design which will save your transportation cost, or as customer requirements

1.Inside packing: Anti-moisture nylon bag + Carton box + woven belt.

2.Outside packing: carton box or wooden case and pallet.

3.According customer requirement.

Port: Shanghai, Qingdao, Tianjin

Lead Time : 7-15days

Please Contact Us:

Miss: Lydia

https://fiberglasshotstick.com

E-mail:sales@fiberglasshotstick.com

WeChat : 86-13752439076 WhatsApp: 86-13752439076

Mob: 86-13752439076 Fax: 86-22-60863016

http://www.frpinsulation.com